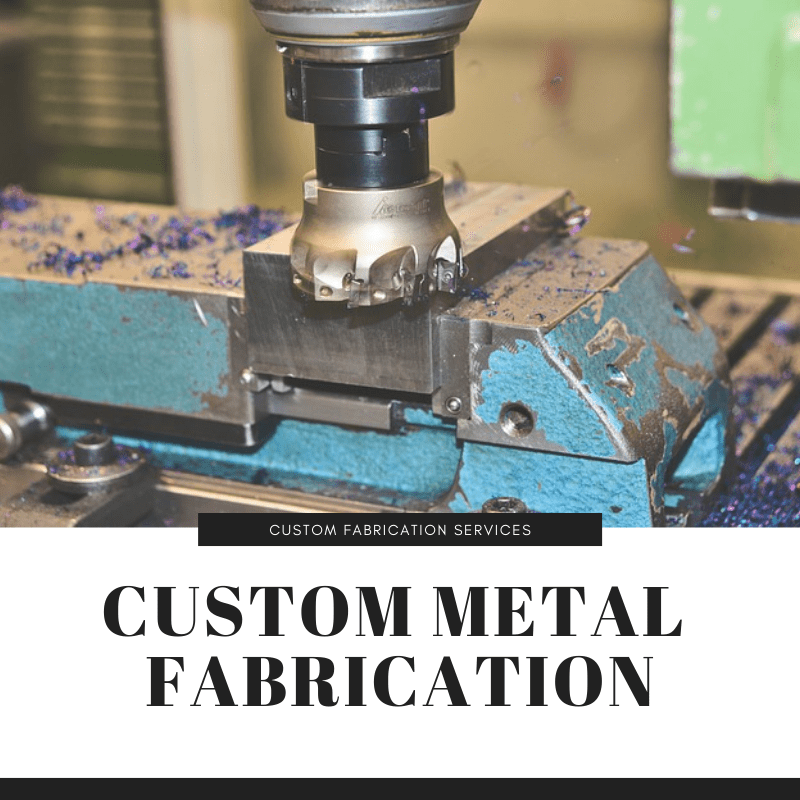

The Process of Custom Metal Fabrication

Custom metal fabrication can be a broad term that means many things. Essentially, it forms metal into a usable product. We have an entire Engineering team ready to design and draw up your next part. This team is ready and willing to design any custom metal component you have in mind. Each type of metal fabrication is a skill to master.

Custom Metal

Our custom fabrication services include the design and concept, product building, finishing, assembly, and packaging.

Product fabrication from the very beginning will need a considerable amount of engineering and planning. Insufficient planning results in poor dimension, improper fitting, and structural weakness. This is why we offer services that prevent this. Things such as Computer Aided Design (CAD) and Tooling Design. CAD allows us to create computer-generated 3D models which will allow us to study the product’s weak points.

Custom Fabrication Services

custom metal fabrication

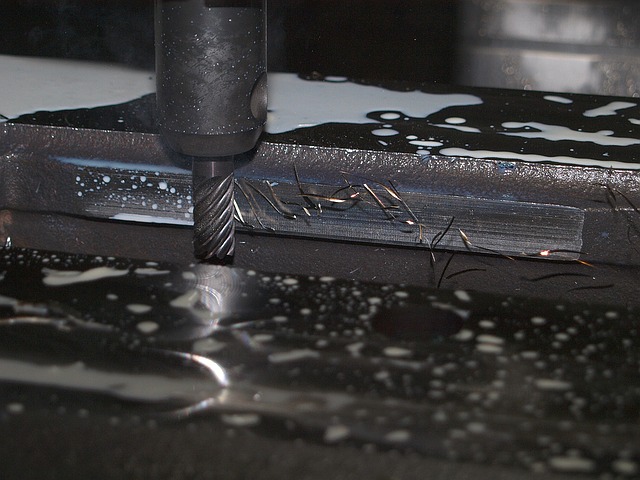

Getting the correct fabrication of process for the product launch is important as well. Here are processes we use at our facility:

- Drilling-bore holes into the metal.

- Assembly-Combine 2 or more components to complete a component

- Bending-Transform the metal into a U or V shape or to create channels

- Custom Finishing-Various finishing or painting that may be done to complete the component

- Punching-Adding decorative features with a punch to the metal

- Turning-rotate the metal piece while cutting to get the finished product look desired for that component.

- Welding-Join two pieces of metal together with heat and pressure.

- Electronics-Adding the electrical components needed.

Finding the Perfect Custom Fabrication Shop

Deciding on the custom fabrication shop is a very important step. When you are looking for a custom fabrication shop remember to look at their experience. Have they been doing this for a long time? Do they have a good reputation? And, ask for references. They should be able to offer some. We are happy to offer references. And, give you any information about our company and its reputation that you’d be interested in.

What metals do the shop tend to work with? Steel is completely different than aluminum. Most custom metal components are made from 304, 316, and 410 steel grades. Stainless steel is used in the medical industry and aluminum in the boating industries, for example. The welding on these metals is a bit different as well as the fabrication. So, understand what material will be used in the component helps. Other industries such as aerospace and aircraft components use Aluminum. Aluminum is easy to machine, has fair corrosion resistance and is easy to work with. However, steel is more cost effective.

Give us a call, we are happy to assist you in your custom fabrication needs. Our staff has many very qualified Engineers as well as tradesmen with the skill to fabricate metal in all kinds of various ways. We are happy to show you around our fabrication facility. Feel free to ask a question as well.