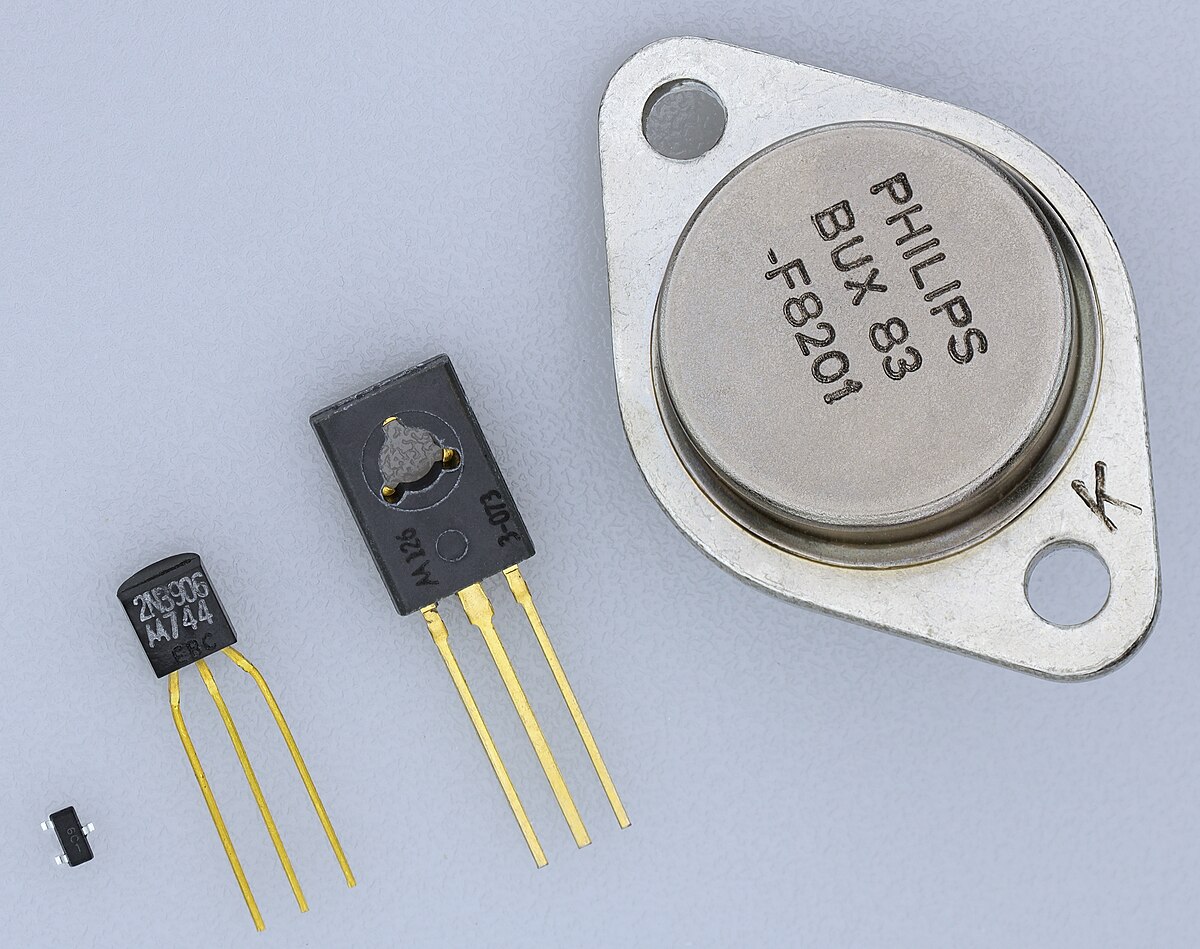

Thermal management in electronic devices is a critical issue at the forefront of modern engineering challenges. As transistors, the building blocks of electronics, are pushed to their physical limits in size and performance, they generate more heat. Removing this heat is essential to maintaining the device’s performance and longevity. Thermally conductive insulators have emerged as a vital solution, offering a means to channel heat away from sensitive transistor components without compromising electrical insulation.

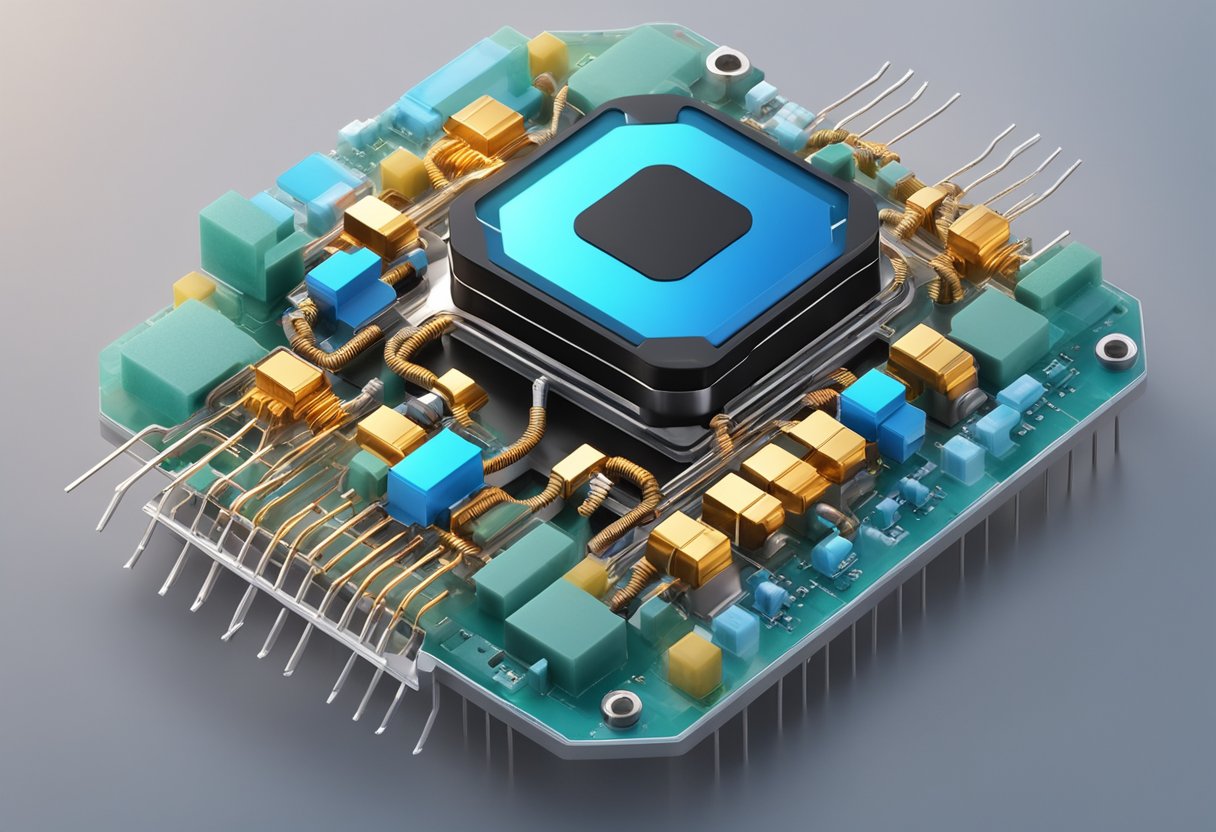

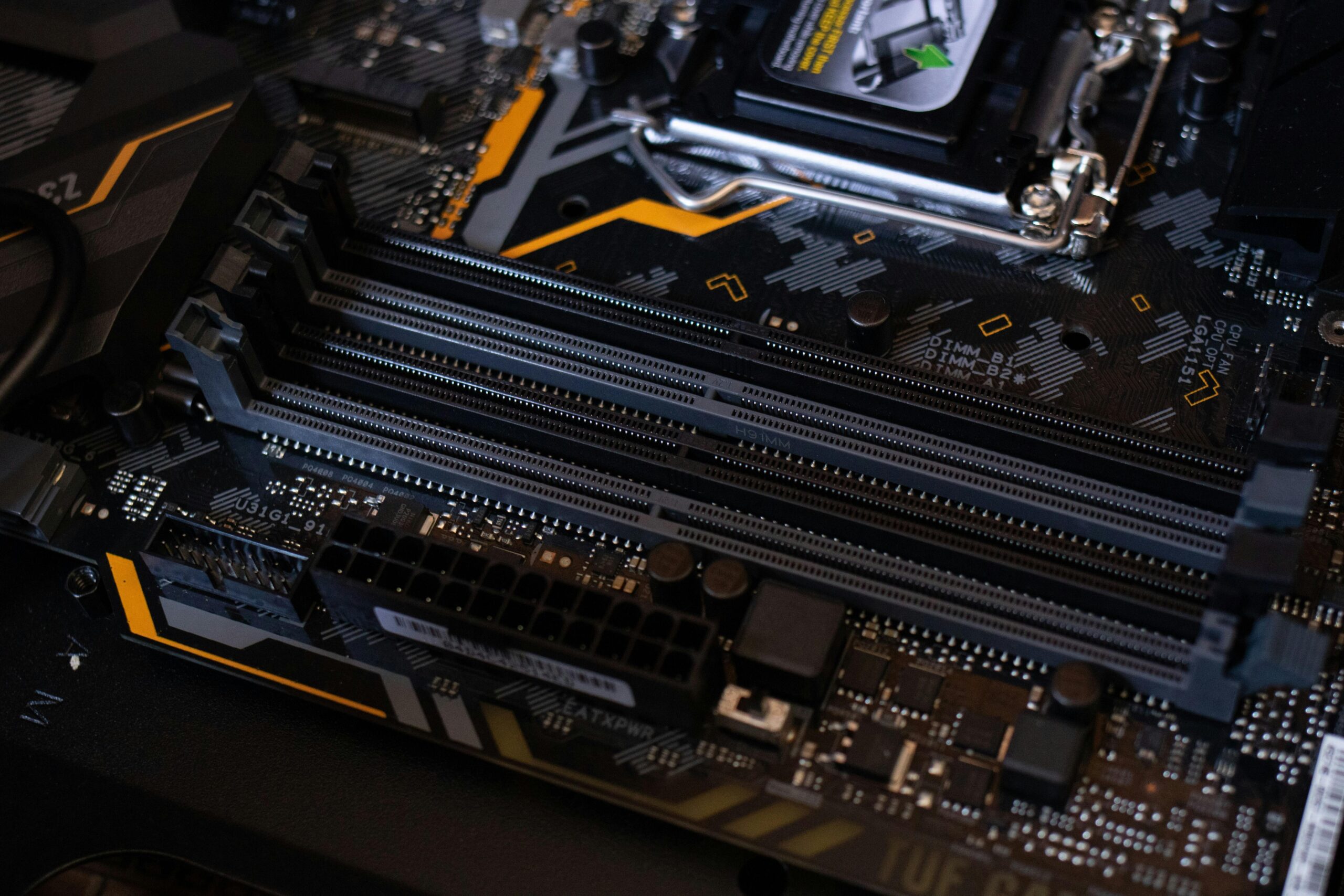

Integrating thermally conductive insulators into transistor design addresses the challenge of heat accumulation in high-density circuits. By effectively transporting heat away from active regions, these materials enable components to operate at optimal temperatures, thus enhancing their reliability. This innovation also plays a crucial role in advancing three-dimensional (3D) integrated circuits (ICs), where managing heat within layered architectures presents a unique set of challenges. The development and application of such insulators directly influence transistor efficiency and are key to sustaining Moore’s Law in the era of nanotechnology.

Key Takeaways

- Thermally conductive insulators are essential for managing heat in densely packed transistors.

- The use of these materials enhances reliability and performance in electronic devices.

- Their application is critical to the development of advanced 3D integrated circuit technologies.

Fundamentals of Thermally Conductive Insulators

Thermally conductive insulators obstruct the flow of electricity while efficiently dispersing heat. They play a crucial role in modern electronics, especially transistors, where managing heat is vital for performance and longevity.

Composition: Thermally conductive insulators often comprise polymer composites. These composites are engineered to have a high dielectric breakdown strength and superior thermal conductivity, which allows them to dissipate heat swiftly during electronic device operations.

Properties:

- Electrically Insulating: They prevent electrical conduction, which is crucial for avoiding short circuits in transistors.

- Thermally Conductive: They swiftly transfer heat away from hot spots, which is pivotal for the reliability of electronic components.

Performance Factors:

- Thermal Conductivity (TC): Measured in watts per meter-kelvin (W/m⋅K), the key parameter that defines a material’s ability to conduct heat.

- Dielectric Strength: This measures an insulator’s ability to resist electrical breakdown at high voltages.

Researchers aim to enhance thermal conductivity without losing essential properties such as lightweight, flexibility, and electrical insulation. For instance, specific polymer composites have been developed for high-voltage insulation and exhibit increased thermal dissipative capabilities.

Materials like Aluminum Nitride (AlN) and hexagonal Boron Nitride (hBN) have been identified as high thermal conductivity insulators that can significantly reduce thermal resistance in multi-layered devices like 3D integrated circuits (ICs).

In transistors, using these insulators aids in heat management, thus enhancing the overall efficiency and preventing overheating-related failures. It is an ongoing research topic, with the industry seeking new composite formulations that balance thermal performance with electrical insulation capabilities.

Role of Insulators in Transistor Performance

The performance of transistors is profoundly influenced by the effectiveness of the insulating materials used for heat management, energy efficiency, and enhancing the devices’ lifetime and reliability.

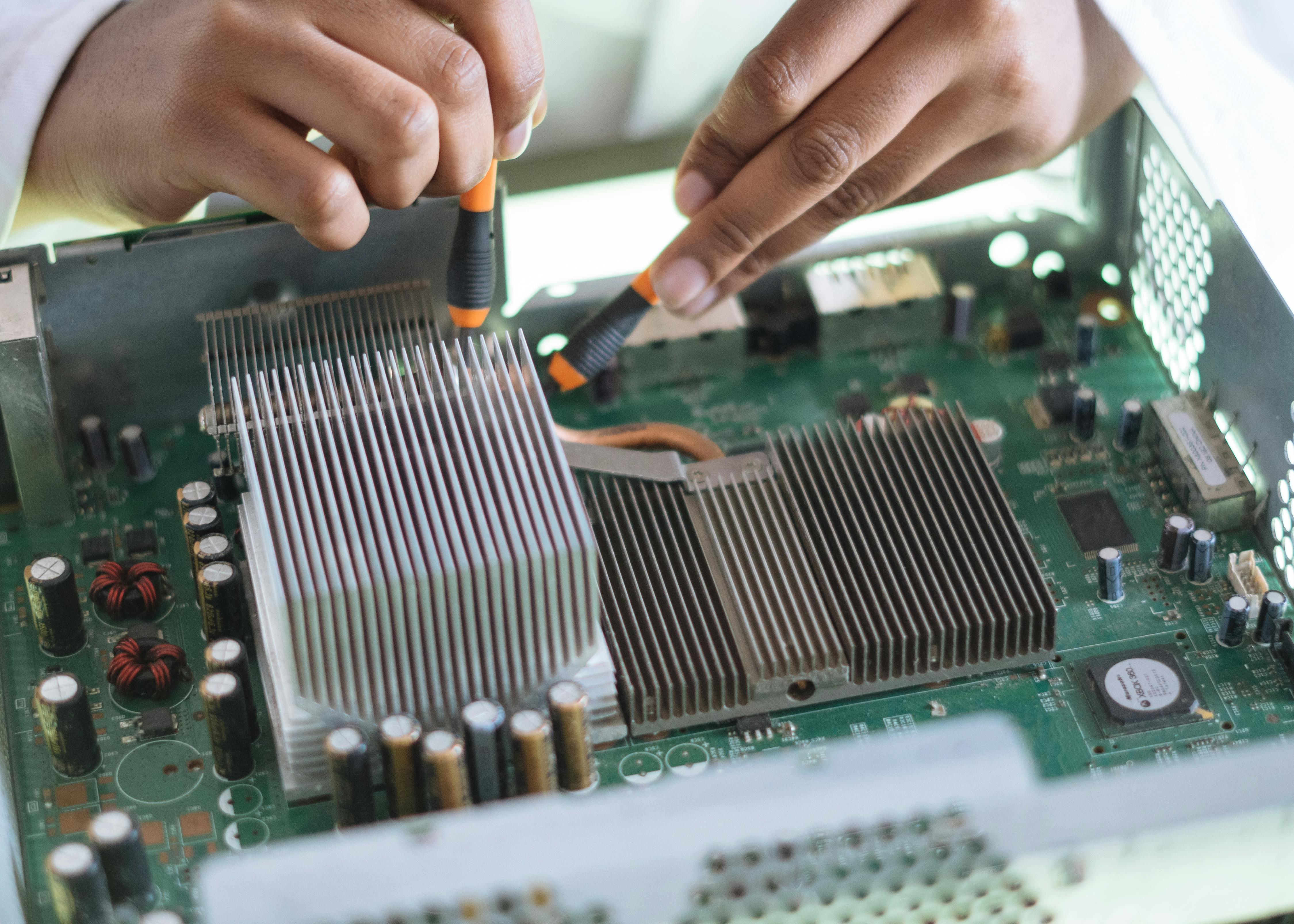

Heat Management

Thermal insulators within transistors play a vital role in heat dissipation. As electronic devices become more compact, the heat generated by transistors increases significantly. High thermal conductivity insulators aid in the distribution and expulsion of this heat, crucially maintaining the operational temperature of the transistor. An example includes using materials to efficiently transfer heat from the transistor layers in 3D integrated circuits.

Energy Efficiency

Insulators with superior thermal management capabilities also contribute to the energy efficiency of transistors. They minimize power loss due to overheating and enable transistors to function optimally at lower power ratings. This reduces energy consumption overall, which is especially beneficial for battery-powered devices. Research has suggested the capacity of certain insulating materials to enhance electrical properties, like electron mobility in n-type polymer transistors, leading to more efficient charge and thermal transport.

Lifetime and Reliability

The lifetime and reliability of transistors are directly affected by the operating temperatures and thermal cycles they undergo. Insulators that cannot effectively manage heat may contribute to premature aging and failure of electronic components. Using robust insulating materials that can withstand high temperatures without degrading ensures that the components retain their performance over time, as evidenced by studies on layered 2D insulators and the ionic crystal CaF2, which have shown promising results in 2D nanoelectronics.

Materials for Thermally Conductive Insulators

Thermally conductive insulators are crucial in managing heat in transistors to ensure reliability and efficiency. Selecting a suitable material can significantly affect the thermal management system’s overall performance.

Ceramic-based Materials

Ceramic-based materials are widely respected for their excellent thermal conductivity and electrical insulation properties. They often serve as the backbone for heat dissipation solutions in electronic devices. Alumina (Al₂O₃) and boron nitride (BN) are commonly used ceramics, with boron nitride being favored for its superior thermal conductivity, which closely resembles that of diamond.

Composite Materials

Composite materials combine different substances to leverage their respective strengths — in this case, improving thermal conductivity while maintaining electrical insulation. Polymer composites enriched with fillers like aluminum nitride or silver particles offer a balance between thermal management and insulative properties. Such composites are engineered to channel heat effectively while preventing electrical conduction, making them ideal for high-voltage applications.

Design Considerations for Transistor Insulators

The appropriate materials and design methodologies for transistor insulators are critical for optimal device performance. These considerations directly influence a transistor’s efficiency and longevity.

Physical Properties

The selection of insulator materials in transistors is governed by a combination of physical properties. Dielectric strength and thermal conductivity are at the forefront of these properties.

- Dielectric Strength: An insulator must have a high dielectric breakdown strength to prevent electrical failure under high-voltage conditions.

- Thermal Conductivity: High thermal conductivity is essential for dissipating heat effectively, as outlined in “High Thermal Conductivity Insulators for Thermal Management in 3D Integrated Circuits,” to mitigate the risk of overheating.

Thermal Interface

The thermal interface is the medium between the heat source and the heat sink. A well-engineered thermal interface significantly enhances heat transfer efficiency.

- Materials: Options include thermal greases, pads, and phase-change materials, each with specific pros and cons.

- Design: The thermal interface must minimize the thermal resistance while maintaining electrical insulation. Effective thermal management is a cornerstone, as per the strategies mentioned in the “Thermally conductive polymer composites for high voltage insulation” review.

By making informed decisions on these fronts, manufacturers can ensure that their transistor insulators are effective and reliable, providing a foundation for advanced electronic systems.

Advancements in Transistor Insulation Technology

Due to their increasing power and heat density, thermal management is a pivotal challenge in modern transistors. Advancements in thermal insulation have been integral to sustaining the performance and reliability of these devices.

Nanotechnology Applications

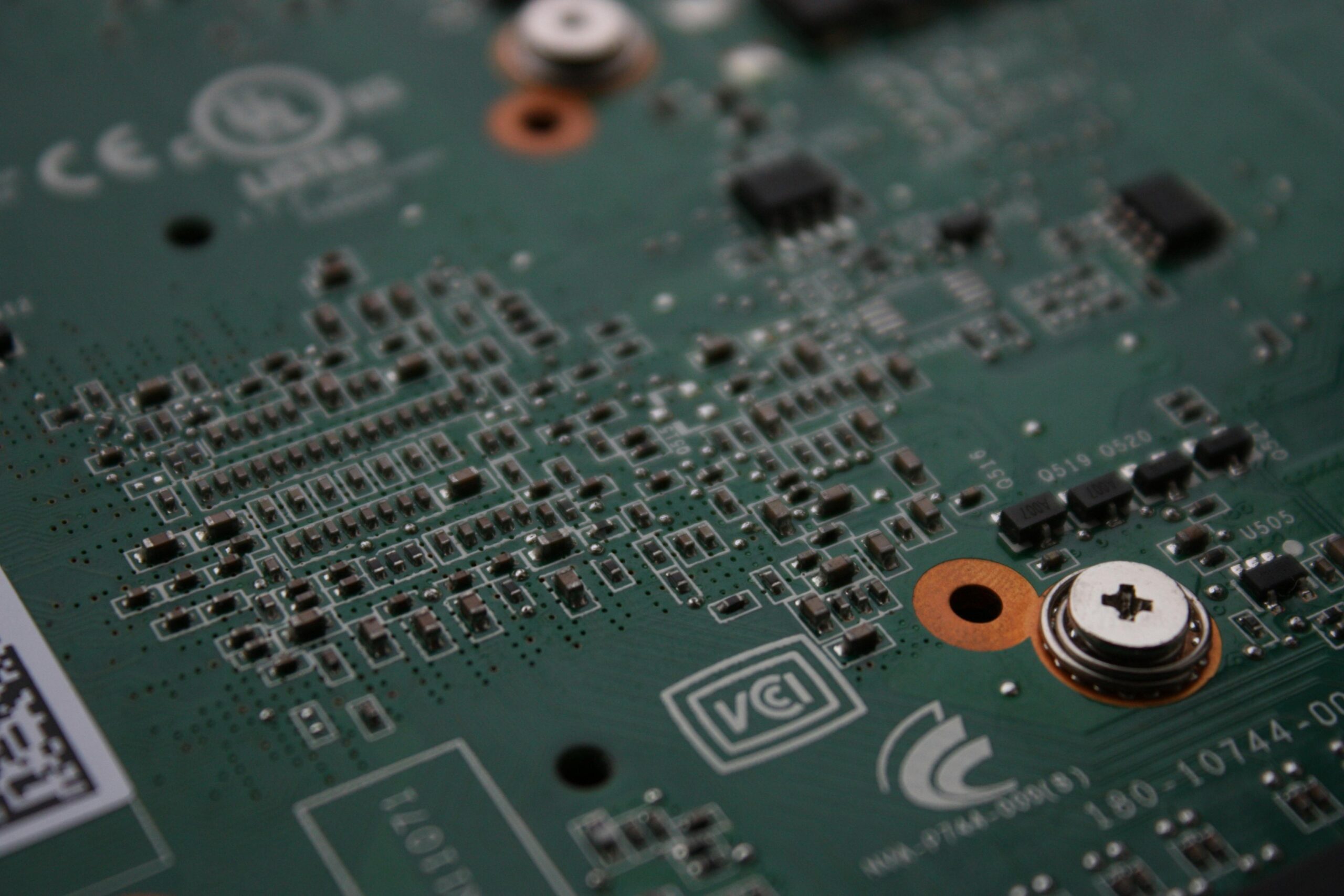

Nanomaterials have proven to be game changers in thermal insulation for transistors. For instance, the emergence of nanocomposites has provided materials that enhance thermal conductivity and preserve electrical insulation. These composite materials incorporate nano-sized fillers with intrinsic thermal conductivity properties, such as boron nitride or aluminum oxide. Advances in thermal-conductive insulating polymer composites with assorted fillers demonstrate a significant increase in heat dissipation capacity while maintaining the necessary insulating characteristics for transistor applications.

Innovative Fabrication Techniques

Developing new fabrication techniques has opened pathways to more efficient thermal conductive insulators. For instance, layer-by-layer assembly methods allow for unprecedented control over the microstructure of insulating materials. Additionally, techniques such as the inclusion of aeolotropism fillers aim to improve heat conduction pathways within insulators. The precision of these innovative approaches is crucial for addressing the heat removal challenges from densely packed transistor layers, as seen in 3D integrated circuits. Thermal management is essential to enable 3D integration in electronics without compromising device performance or lifespan.

Frequently Asked Questions

The following subsections address common inquiries about the application of thermally conductive insulators in transistors, clarifying their benefits and the significance of thermal management in electronic devices.

What are the key benefits of using thermally conductive insulators in transistor applications?

Thermally conductive insulators in transistors greatly enhance heat dissipation, improving device reliability and performance. They allow for more efficient cooling, preventing thermal hotspots that can cause device failure.

How does thermal conductivity impact the performance of electrical insulators in high-temperature environments like rocket engines?

In environments such as rocket engines, electrical insulators with high thermal conductivity dissipate heat rapidly, protecting sensitive components from thermal damage and enhancing overall performance under extreme conditions.

In what ways are transistor insulator pads enhanced by incorporating materials with high thermal conductivity?

Incorporating materials with high thermal conductivity into transistor insulator pads leads to lower thermal resistance, which facilitates the removal of excess heat and enhances the transistor’s operational stability and lifespan.

What advantages do thermally conductive, electrically insulating epoxies provide in electronic component manufacturing?

Thermally conductive, electrically insulating epoxies bridge the gap between thermal management and electrical safety, offering secure bonding while efficiently managing the heat flow away from the critical parts of electronic components.

How is the thermal conductivity of materials measured, and why is it important for transistor function?

Thermal conductivity is measured in watts per meter Kelvin (W/mK), quantifying how well a material conducts heat. High thermal conductivity in insulators helps maintain operational temperatures within safe limits, preserving transistor function and preventing overheating.

Can a material with higher thermal conductivity act as an effective thermal insulator in electronic devices?

Yes, a material can exhibit high thermal conductivity and still function effectively as an insulator in electronic devices. Such materials allow for rapid heat transfer away from hotspots while maintaining electrical isolation, which is critical for electronic device stability and function.