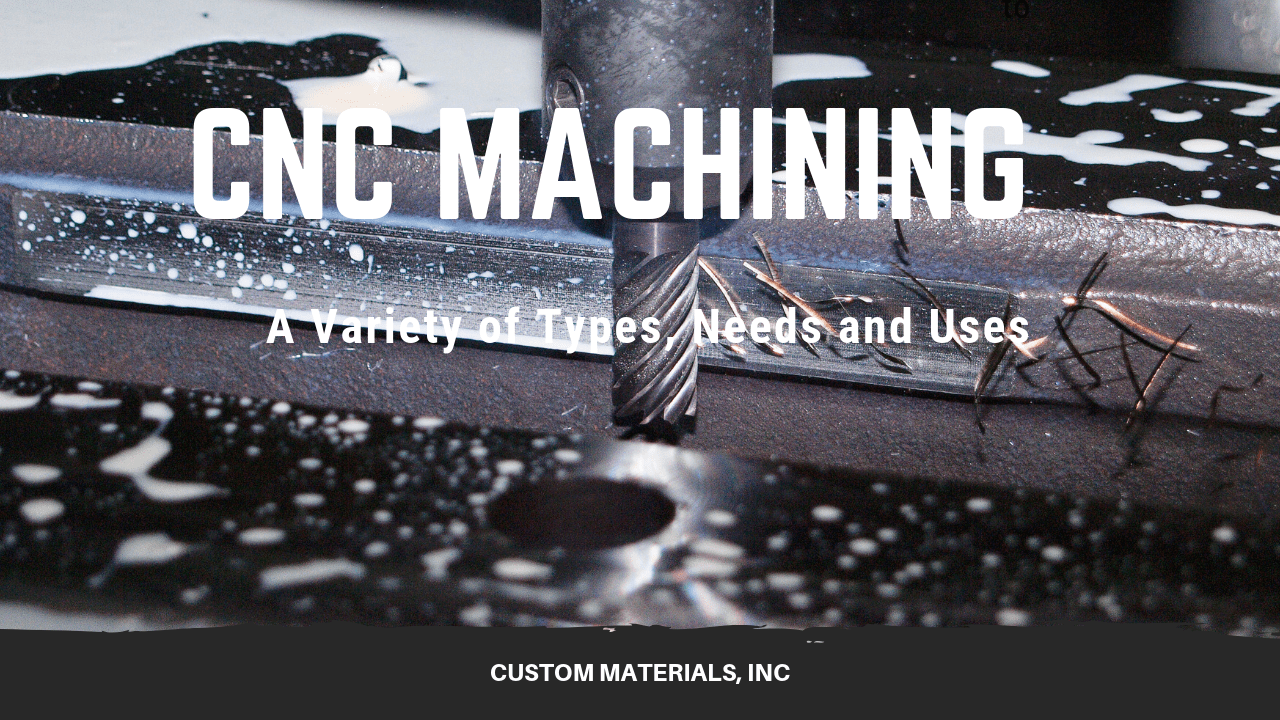

CNC Machining Today

If you are looking for accuracy and precision, there is nothing better than CNC (Computer Numerical Control) machined parts (CNC Machining). These parts are programmed on a computer and CNC machined to the finest of tolerances. This is a more expensive way to make custom parts as opposed to plastic injection molding or other forms, however, when the tolerances need to be there, it is the best. CNC Machining is also a great way to make one of a kind custom parts and parts for design testing. CNC Machining is most accomplished in custom fabrication shops or specialty machine shops with staff engineers.

The different types of CNC Machines

CNC Machining

CNC machines move on two axis the x-axis and y-axis followed by the third the z-axis. Some machines run on all 3 and some only the two. There are also 5 axis CNC machines as well, these refer to the degrees of freedom the machine cuts. A three-axis machine can run x, y, and z. However, a 5 can run x, y, z, and 2 rotational axis. This makes the possibilities almost endless and can operate at higher speeds, giving them a lower cost to run. There are even 6 axis machines which are 3 perpendicular axis and three rotary axis. Other forms of CNC machines are 5 axis, 6 axis, Lathes, routers, milling, plasma cutters, and laser cutters.

Routers: A CNC Routers can engrave things such as plastic, metal, and wood and is a very common type of CNC. Everything is done by computer. This leaves no room for human error.

Plasma: Plasma cuts 2D shapes. It is capable of cutting metal and wood for custom fabrications. This machine doesn’t use as much energy and uses a plasma torch to penetrate the metal and wood.

Laser: A laser CNC acts in a similar manner to plasma only it uses a laser to cut the metal.

3D printer: 3D printers use CNC technology. They are a type, perhaps a cousin, the CNC machinery. But, act very similar to that of a laser CNC for cutting. 3D printing has gained popularity for prototypes. 3D Printers in recent years have become affordable and readily available.

Pick and Place: Pick and place CNC Machines consist of several nozzles that pick up various electrical parts and components. These are used to construct cell phones and other electronic boards.

CNC Machining and the Automotive Industry

CNC Machining Today

CNC Machining parts are all around, they are the glue that holds the automotive industry together. They hold your car together as well as all the gears used in the transmission and engine are all made by CNC Machining, as the tolerances of these components are very tight. With modern technology, CNC components have become more and more affordable as well.

Engineers first need to design up the part using a CAD program on the computer. This takes a special skill set that understands the program they will be working in. From there, the computer will translate the model into a language that the CNC machine speaks. This allows the machine to have precision cuts without any human error. This means these parts can be replicated over and over again and hold to the same tight tolerances given.

CNC Machining Consultation

Custom Materials can provide a free consultation on your composite CNC Machining needs. Call us or drop us an email to get started. Our experienced engineers and floor staff can be an additional resource for your project.

You must be logged in to post a comment.